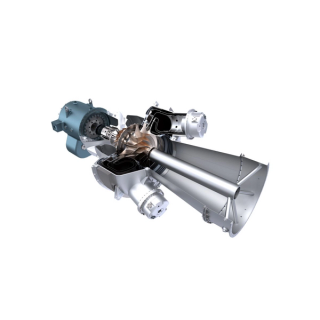

OPRA OP16 Gas Turbine

State-of-the-art OPRA OP16 Gas Turbine designed to enable high fuel flexibility, a small footprint, long operating hours between overhauls and low emissions, reducing your operation costs and world’s energy resources spending.

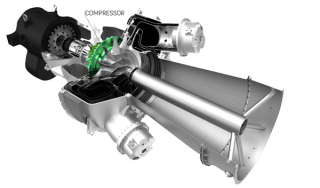

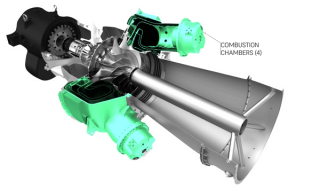

The OP16 Gas Turbine is well known for its fuel flexibility. The gas turbine has a dual-fuel combustion chamber with switching between liquid and gaseous fuels under load; the widest range of acceptance of the LHV of the fuel within power generation industry, from 5 MJ/kg; the ability to work with dynamically changing fuel composition; proven resistance to contaminated fuels, including those with a high content of H2S up to 7%;dry low emission combustion chamber; low fuel gas pressure requirements.

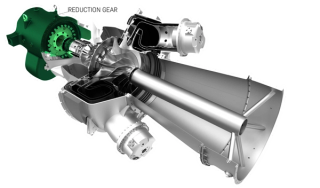

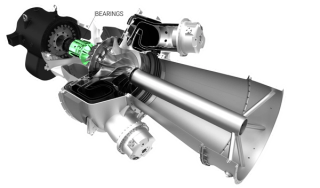

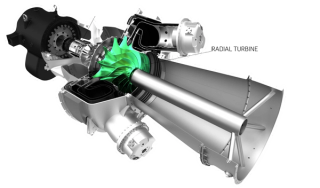

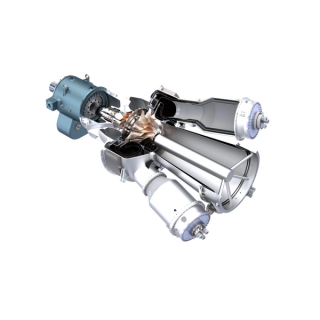

The OPRA OP16 Gas Turbine has an all-radial design which provides robustness, reliability, and low-maintenance. The four external can-type combustors allow for easy access to the turbine hot flow path reducing the amount of downtime. The robust design with the bearings located in the cold section, allows the OPRA OP16 to run for 42500 hours before an overhaul is recommended.

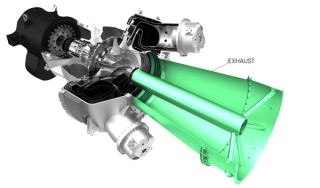

Designed to be an innovative CHP machine with a superior heat-to-power ratio and elevated exhaust temperatures, the OPRA OP16 demonstrates remarkable efficiency for combined heat and power (CHP) applications. The overhung design with all bearings in the cold section is ensuring an oil-free exhaust flow which can be used for direct drying and food-processing applications.

The OP16 radial turbine's exceptional power density enables a compact and streamlined design, boasting just a third of the moving parts found in conventional equipment. This sleek package design not only occupies minimal space but also showcases its lightweight construction. Enclosed within two 20 ft containers, the OPRA OP16 Gas Turbine ensures swift and effortless installation. These compact and lightweight packages facilitate convenient transportation and seamless equipment setup.

By using enhanced combustor design of the OP16, you can significantly reduce NOx emissions compared to conventional combustion systems. The precise control of fuel-air mixtures and combustion parameters enables efficient turbine operation across varying load demands and ambient conditions. This flexibility enhances the turbine's ability to respond to grid requirements and market demands efficiently. This is important for environmental compliance and to meet increasingly stringent emission regulations.

The OP16 Gas Turbine is engineered to operate on hydrogen, a clean and sustainable fuel source. By harnessing hydrogen, a viable alternative to traditional fossil fuels in gas turbine power plants, we embrace an eco-friendly solution. The combustion process of hydrogen within the gas turbine solely yields water vapor, leaving no harmful emissions behind.

OP16-3A

- 𝐃𝐢𝐟𝐟𝐮𝐬𝐢𝐨𝐧 𝐜𝐨𝐦𝐛𝐮𝐬𝐭𝐨𝐫

- Robust diffusion type combustor

- Gaseous fuels between 25-70 MJ/kg

- Liquid fuels between 38-43 MJ/kg

- Dual fuel operation

OP16-3B

- 𝗗𝗿𝘆 𝗹𝗼𝘄 𝗡𝗢𝘅 𝗰𝗼𝗺𝗯𝘂𝘀𝘁𝗼𝗿

- Pre mix low NOx combustor

- Gaseous fuels between 30-52 MJ/kg

- Liquid fuels between 41-43 MJ/kg

- Diesel as a backup fuel

OP16-3C

- 𝗟𝗼𝘄-𝗰𝗮𝗹𝗼𝗿𝗶𝗳𝗶𝗰 𝗳𝘂𝗲𝗹 𝗰𝗼𝗺𝗯𝘂𝘀𝘁𝗼𝗿

- Advanced diffusion type combustor

- Gaseous fuels down to 5 MJ/kg

- Liquid fuels down to 16 MJ/kg

- Dual fuel operation

The OPRA OP16 gas turbine engines are integrated into a comprehensive range of standard packages, meticulously developed to deliver optimal performance, reliability, and an extended lifecycle.