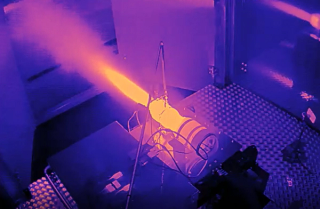

This quarter marks the start of a new era for Destinus as hydrogen tests become a reality. After months of development and preparation, we finally began testing our in-house built afterburner technology – using hydrogen! This new piece of hardware was mounted onto our test stand in Switzerland and we fired it with hydrogen fuel. This test stand will become a part of our broader test facility for hydrogen technology developments.

When do you need Afterburners?

Conventional turbojet or turbofan engines, like those found in commercial planes, consist of four main parts: (1) compressor, (2) combustion chamber, (3) turbine, and (4) nozzle. These engines work well for subsonic velocities, and sometimes up to low supersonic velocities. Afterburner technology, however, is paramount to achieving high supersonic velocities. They are found on practically all jet fighters because of the extra thrust generated, which is necessary to pass the sonic barrier without a prohibitively heavy and large engine. Afterburners can also be combined with ramjets in the future, producing a nicely integrated propulsion system.

Afterburners increase Performance

At supersonic speeds, classical turbojet engines are limited in their performance due to hot temperatures created in the engine by the fast air flow. Afterburners increase the thrust of the engine by injecting additional fuel in the nozzle jet flow, before it leaves the engine. This allows us to boost the engine power without increasing the upstream temperature. Nevertheless, the energy added by afterburning can make the engine nozzle extremely hot. Cooling technology for the nozzle using Hydrogen fuel is being developed using our new test facility.

Hydrogen is the Enabling Fuel

Afterburner technology is key to our mission success and we will be scaling these tests over the coming years. Our afterburners use hydrogen as fuel instead of kerosene because of several technological advantages. Beyond having zero carbon emissions, hydrogen has a much higher energy content per unit mass compared to kerosene. This means that engines are more fuel efficient when using Hydrogen. It also has a short ignition delay, which means that combustion systems can be made less complicated than some kerosene afterburners.

Test Results & Next Steps

The purpose of the recent afterburner experiments was to measure the chamber and exhaust temperature, as well as to measure the additional thrust produced. With such measurements, we are learning about the various hydrogen phenomena involved and validating our engineering models. This supports the development of larger propulsion systems powered by hydrogen for our future flight prototypes and products. In coming months, we will use the same test stand to test other components related to our propulsion system. This instrumented test stand is placed within a container, making it easy to transport to other test locations when needed.

This afterburner is currently being integrated onto our Jungfrau prototype. Watch this space as we will soon announce our first flight with hydrogen!