Industrial and Commercial

Optimize Your Heat & Power Generation

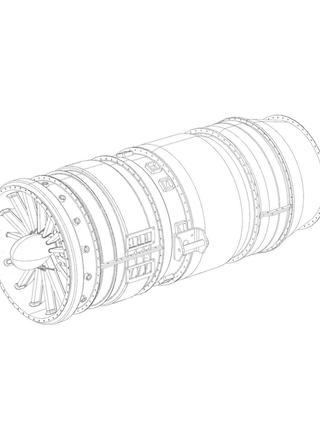

The OP16 Gas Turbine enables...

- High exhaust gas temperature (570°C) for steam production or direct drying applications

- High heat-to-power ratio 3:1

- Clean exhaust gas free from lube oil contamination

- Modular design, quick installation, production downtime is minimized

- Energy independency Heat & Electricity are on-site

- Minimum maintenance, high availability

- Remarkably low emissions down to 15 ppmv of NOx

- Low noise down to 75dB

- Load acceptance and rejection up to 100%

- Stable operation across the entire load range 1-100%

- Island mode operation across the entire load range 1-100%

The pulp & paper and tissue industries are energy intensive. High temperature heat is needed for steam generation and drying. Destinus Energy has multiple references in the field and is a perfect match for small to medium size cardboard, tissue and paper plants.

The food industry, encompassing sectors such as dairy, breweries, sugar mill factories, and agro, demands elevated temperatures for various operations including drying, processing, and cleaning. With its assured oil-free exhaust, the OPRA OP16 Gas Turbine emerges as an ideal choice for these applications. Destinus Energy boasts successful references in the food industry, including the implementation of our technology in a starch manufacturing plant.

The ceramic industry has heat-intensive processes such as kiln firing and drying. The heat-to-power ratio in the ceramic industry is nicely aligned with the OPRA OP16 Gas Turbine making it an excellent match for drying applications.

The chemical industry including mineral fertilizers requires vast amounts of heat, steam and energy for its production processes. Destinus Energy has various references in this field.

The optimal power generation solution for refineries is combined heat and power (CHP), which harnesses OPRA's remarkable heat-to-power ratio. This exceptional ratio makes it an ideal choice for CHP applications. Notably, the turbine's elevated exhaust temperature and significant flow enable efficient steam generation, a critical requirement in most refinery processes. Moreover, it allows for the utilization of certain byproduct gases from refineries as an additional fuel source, effectively reducing emissions.

The rubber industry requires large amounts of high-temperature heat for vulcanization, curing and molding applications. Steam is typically used as a heat transfer medium in these processes.

In the gypsum, cement and bricks production, high temperature heat is often required for drying, calcination, or other thermal processes. e.g. The heat-to-power ratio in the gypsum industry is nicely aligned with the OPRA OP16 Gas Turbine making it an excellent match for drying applications.

The wood processing industry encompasses a range of sectors such as chipboard, MDF, MDP, Plywood, and OSB, all of which rely on processes involving electricity, and steam. The OP16's elevated-temperature exhaust gases present an opportunity for their effective utilization in steam generation or direct drying, both of which play a pivotal role in wood processing operations.

The OP16 Gas Turbine play a significant role in the crypto mining and data center industry by addressing the power and cooling requirements of these high-energy-consuming operations. The OP16 provide reliable and efficient on-site power generation for crypto mining farms and data centers. These facilities require large amounts of electricity to power their high-performance computing equipment. The OP16 offers high power density, quick start-up times, island mode operation, and the ability to ramp up power output rapidly, making them suitable for meeting the dynamic power demands of crypto mining and data center operations.

Commercial buildings such as hospitals, hotels, universities, and shopping centers often require an independent energy source with a small footprint. If in addition heat is needed e.g. for hot water generation, Destinus Energy can provide the perfect distributed energy, trigeneration, backup and peak power solutions.

The OP16 features as a dependable backup power source, playing a crucial role in bolstering grid stability and balancing electricity supply and demand. In instances when renewable energy generation is insufficient or unavailable, the gas turbine swiftly ramps up and offers essential grid stability control, guaranteeing a consistent and reliable power supply.

The OP16 Mobile Package can be deployed to remote locations or areas without reliable grid infrastructure, providing temporary power for construction sites, disaster or emergency response, remote operations, or events. The OP16 provides reliable and fast-starting emergency power in critical situations.