Waste to Energy

Turn Your Waste Gases Into Energy

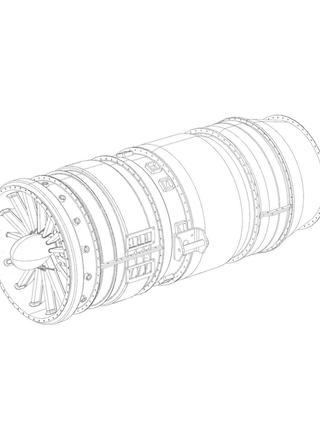

The OP16 Gas Turbine enables...

- Use of ultra low-calorific, contaminated fuels e.g. syngas, biofuels, COG

- Excellent solution for decentralized Waste to Energy

- Low maintenance cost

- High hydrogen and CO fuels are accepted

- Operate with dynamically changing composition and LHV

Biogas is a renewable fuel generated through the anaerobic digestion of organic matter, such as agricultural waste, sewage sludge, or food waste. It primarily consists of methane (CH4) and carbon dioxide (CO2), with impurities like hydrogen sulfide (H2S),siloxanes or other particulates. The OP16 gas turbine is specifically designed to handle these features of biogas to effectively generate power.

Syngas, also known as synthesis gas, is a mixture primarily composed of carbon monoxide (CO) and hydrogen (H2). It can be produced through various processes, such as steam reforming of municipal waste, gasification of wasted tires, or partial oxidation of other hydrocarbons. The OP16 gas turbine is engineered and adapted to effectively combust syngas, even with relatively high impurities.

Pyrolysis oil, also referred to as bio-oil or biomass oil, is a renewable fuel produced through the pyrolysis process, which involves heating selected types of feedstock in the absence of oxygen. It typically contains a mixture of organic compounds, including acids, phenols, and other impurities. The specific composition and properties of pyrolysis oil can vary depending on the feedstock used and the pyrolysis process employed. The OP16 is adapted to handle the unique characteristics of pyrolysis oil and effectively utilize it as a fuel source.

Non-condensable (pyrolysis) gas is a valuable by-product in the pyrolysis process. Instead of being flared or combusted directly in a gas-fired boiler, the OP16 offers a highly efficient solution to transform this gas into electricity and heat, reducing energy costs and greenhouse gas emissions simultaneously.

Industrial off gases or tail gases are the byproducts or waste gases produced during various industrial processes. These off gases often contain combustible components, as well as some contaminations that can be successfully utilized as fuel in the OP16 gas turbines. With the OP16 gas turbine, you can effectively harness these off-gases to meet your process’ electricity, direct heating, and steam requirements.

Ammoniacal gas consists primarily of ammonia (NH3) and can be derived from various sources, such as industrial processes, agricultural activities, or ammonia production plants. The suitability of ammonical gas as a fuel for the gas turbine depends on its composition and purity, which can be analyzed for effective utilization.

VOCs are emitted during various production processes like painting or chemical manufacturing. VOC gases are also generated during curde oil transportation and storage. Whenever crude oil is stored in large containers, certain components “gas out” and form VOCs which needs to be vented into the atmosphere. Rather than resorting to flaring VOCs produced by oil tankers during it’s transportation and transfer, the OPRA OP16 Gas Turbine enables their valuable utilization as fuel for onsite power generation.

Landfill gas, generated by the decomposition of organic waste in landfills, primarily contains methane (CH4) and carbon dioxide (CO2), with additional gases. The OP16 gas turbine's combustion system is designed to operate efficiently even with varying Lower Heating Value (LHV) in fuel, making it suitable for utilizing landfill gas.

Digester gas is produced through the anaerobic digestion of organic waste in facilities such as wastewater treatment plants, agricultural digesters, or food waste digesters. The methane-rich by-product serves as a valuable fuel for power and heat generation when utilized with the OP16 gas turbine.

The OP16 Gas turbines are designed to handle coal bed methane (CBM) as a fuel source. CBM, also known as coal seam gas or coal mine methane, is a natural gas that is trapped within coal seams underground. Unlocking its potential for efficient power generation.

COG is a byproduct of the coke production process in steel manufacturing, primarily consisting of hydrogen (H2), methane (CH4), carbon monoxide (CO), and small amounts of other gases. Before being used as fuel, COG is typically subjected to treatment processes to remove or reduce these impurities. The OP16 gas turbine can operate with COG even with minimal treatment, enabling its use as a fuel source.

BFG is a byproduct of the iron and steel production process, specifically the blast furnace. Blast furnace gas holds high carbon monoxide (CO) content and low heating value. However, the OP16 gas turbine is designed toutilize BFG for efficient power and heat generation.

Methanol is a liquid alcohol that can be produced from various feedstocks, including natural gas, coal, or biomass. It has been used as an alternative fuel in various applications, including power generation. The OP16 gas turbine offers compatibility with methanol, accommodating its low viscosity and challenging lubrication properties for efficient utilization.